Oster Pipe and Bolt Threading Machines for Industrial Applications

The Oster line of pipe & bolt threading machines has served the industrial world for over 125 years. Our rugged, heavy-duty equipment is built to last decades in factory production environments. With unmatched production and power capabilities, Oster threading machines are the highest quality and longest-lasting industrial pipe and bolt threaders produced today. Oster pipe and bolt threading equipment is reliable, accurate, and available in multiple models with various configurations.

Choosing the Best Industrial Pipe and Bolt Equipment

Not sure which bolt threading machines are best for your needs? Contact us or request a quote, and our team will gladly assist you in finding the best threader for your application. Purchasing a threading machine that meets your exact needs is crucial. Depending on your application, you’ll need to consider the requirements for your pipe and bolt threader, including:

- Capacity

- Speed

- Size

- Oiling type

- Chucking type

- Thread-cutting oil

- Rotating die heads and threading dies

- Attachments

Types of Oster Industrial Threading Machines

792ALX Threading Machine

The 792ALX Threading Machine is our flagship pipe and bolt threader. The 792ALX features high production rates at a low entry cost. The rotating X1 Diehead allows for increased production over a standard bolt and pipe threading machine and also creates a safer work environment because the concern over long pieces of rotating material is eliminated. The 792ALX can produce up to 200 threaded ends per hour and cut right and left-hand threads in a single pass.

| General Specification | |

| Pipe Threading Capacity: | 1/8" to 2" |

| Bolt Threading Capacity: | 1/4" to 2" |

| Standard Die-Head: | Oster Rotating Die-Head |

| Die Symbol/Style Used: | X1 |

792 / 794 LX Industrial Threading Machine

The 792/794 LX Threading Machine is oriented for heavy-duty pipe threading, with a 2” bolt and pipe threading capacity. This machine can change spindle speeds at the flick of a wrist with the infinitely variable speed drive. The 792/794 LX can be equipped with Swing-Over style tooling for convenient pipe threading or Slide-In style tooling for left-hand and right-hand bolt threading.

| General Specifications | |

| Pipe Threading Capacity: | 1/8" to 2" |

| Bolt Threading Capacity: | 1/4" to 2" |

| Standard Die-Head: | Quad Slide-In, Universal Slide-In |

| Die Symbol/Style Used: | Quad and 300 |

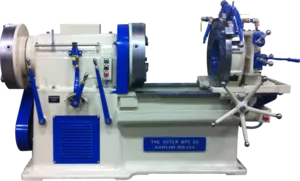

784 Threading Machine

The 784 Threading Machine is the world’s most rugged and versatile quality-built 4” bolt and pipe threading machine. Capable of cutting both right-hand and left-hand threads, this machine can perform Victaulic grooving, cut-off, beveling, weld prep, and more at high threading capacity. This machine will do almost anything you can think of in the pipe threading and preparation realm and will continue doing the job for decades.

| General Specifications | |

| Pipe Threading Capacity: | 1/2" to 4" |

| Bolt Threading Capacity: | 3/8" to 3" |

| Standard Die-Head: | Quad Slide-In, 74, Universal Slide-In, 784 |

| Die Symbold/Style Used: | Quad, 74, 300, 784 |

716 Threading Machine

The 716 Threading Machine is a versatile pipe & bolt threading machine with a single diehead covering a 1” to 6” pipe range.

| General Specifications | |

| Pipe Threading Capacity: | 1" to 6" |

| Bolt Threading Capacity: | 1" to 4" |

| Standard Die-Head: | One, adjustable to handle all sizes in the stadard range |

| Die Symbol/Style Used: | 704 - 6 |

8R Oster Pipe Threading Machine

The 8R Threading Machine provides the finest quality, design, and performance in the category of large-capacity pipe threading machines. The 8R Threading Machine has an excellent thread capacity and can thread up to 8” NPT Pipe in a single pass.

| General Specifications | |

| Pipe Threading Capacity: | 2 1/2" to 8" |

| Bolt Threading Capacity: | 2" to 6" |

| Standard Die-Head: | One, adjustable to handle all sizes in the stadard range |

| Die Symbol/Style Used: | 8R |

12R Oster Pipe Threading Machine

The 12R Threading Machine is one of the largest pipe threading machines currently available for pipe fabrication, capable of threading up to 12” NPT Pipe in a single pass. These machines are exceptionally durable and last for generations.

| General Specifications | |

| Pipe Threading Capacity: | 3 1/2" to 12" |

| Bolt Threading Capacity: | N/A |

| Standard Die-Head: | One, adjustable to handle all sizes in the satandard range |

| Die Symbol/Style Used: | 12R |

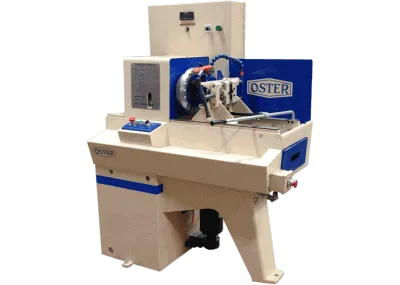

582A Threading Machine

The 582A Threading Machine is a high-production portable bolt and pipe threading machine with the X1 Rotating Die head. With a rotating diehead the workpiece remains stationary, improving production rates and providing a safer work environment. Capable of threading pipe or bolt, right-hand or left-hand threads available.

| General Specifications | |

| Pipe Threading Capacity: | 1/8" to 2" |

| Bolt Threading Capacity: | 1/4" to 2" |

| Standard Die-Head: | Oster Rotating Die Head |

| Die Symbol/Style Used: | X1 |

582 / 584 Automatic Pipe Threading Machine

The 582/584 Threading Machine is a portable production threader for multi-hour threading. A variable speed drive from 22-58 RPM and a rotating die head allow you to use the most economical speed for your job.

| General Specifications | |

| Pipe Threading Capacity: | 1/8" to 2" |

| Bolt Threading Capacity: | 1/4" to 2" |

| Standard Die-Head: | Quad Slide-In (582), Universal Slide-In (582), Quad Swing-Over (584) |

| Die Symbol/Style Used: | Quad and 300 |

654 / 655 Industrial Threading Machine

The 654/655 Threading Machine provides a versatile, heavy-duty, portable pipe, conduit, and bolt threading machine. The 654/655 Threading Machine can be equipped with either Swing-Over style tooling for easy pipe threading or with Slide-In Style tooling capable of cutting left-handed and right-handed bolt threads.

| General Specifications | |

| Pipe Threading Capacity: | 1/8" to 2" |

| Bolt Threading Capacity: | 1/4" to 2" |

| Standard Die-Head: | Quad Swing-Over, Quad Slide-In, Universal Slide-In |

| Die Symbol/Style Used: | Quad and 300 |

Additional Information About Automatic Pipe & Bolt Threading Machines

Thread cutting machines are commonly available in portable, industrial, and high-production varieties. These variations allow specialty uses and are designed for unique applications, from small-scale projects to large-scale production operations. Oster specializes in heavy-duty industrial and high-production threading machine styles to suit your rigorous demands.

Threading machines can process a wide variety of materials for industrial fabrications. Common materials for pipe threading include black pipe, copper, brass, red brass, cast iron, stainless steel, steel, PVC, and more.

Benefits of Industrial Threading Machines

Bolt threading and pipe threading machines offer excellent machining solutions, maintaining uniformity while threading pipes. They are ideal for a wide range of industries, especially those in heavy-duty, harsh environments that rely on consistent results. Benefits of pipe threading machines include:

- Accurate threading at both ends

- Portability

- Easy maintenance

- Efficient performance

- High-volume production capabilities

Dark Thread Cutting Oil for Oster Pipe Threading Machines

Keep threads cool and reduce friction with Oster’s Superior Threading Oil (OSTO) dark thread-cutting oil. Our high-quality dark thread cutting oil increases the life of your die and ensures perfect threads every time. OSTO outperforms competitors and is formulated to have a vise-like grip on the work material while preventing chip welding. Best of all, OSTO has an infinite shelf life and never goes bad or breaks down during threading.

Contact Oster Manufacturing Today

Contact us to order our industry-leading thread equipment, request a quote for pricing information, or reference our Pipe & Bolt Threading Machine User Guide for operation information. As an industry-leading threading machine manufacturer with over 125 years of experience, Oster Manufacturing provides the highest quality, most reliable equipment manufactured entirely in America. We are dedicated to producing threading machines that last for generations.