Decoding Bolt Thread Sizes: Exploring UNC and UNF Standards

Understanding bolt thread sizes, specifically UNC (Unified National Coarse) and UNF (Unified National Fine), requires delving into the distinctions between threads per inch (TPI) and thread pitch. TPI serves as the measurement for bolts and other fasteners under the imperial measuring system, determined by the number of threads per inch. In contrast, metric bolts are evaluated based on their length and pitch, which represents the distance between threads measured in millimeters.

By grasping these fundamental differences, you can navigate the intricacies of bolt thread sizes with confidence. UNC and UNF standards play a crucial role in determining the compatibility and performance of fasteners, ensuring optimal fit and functionality.

Starting a new bolt threading project? Refer to the chart below for UNC & UNF size conversions or browse our selection of bolt threading machines.

Best Seller

Dark Threading Oil

.webp)

- Increases Die Life

- Ensures Perfect Threads

- Prevents Tool Wear

What is The Difference Between UNC Threads & UNF Threads?

Unified Thread Standard

The Unified Thread Standard was established in 1949 by the United States, Canada, and Great Britain to define standards for fastener threads based off thread form, allowances, tolerances, and specific designations. The designations provided under this series factor in both TPI and thread pitch, with UNC & UNF being two of the most common designations used.

UNC VS UNF

UNC stands for unified course pitch threads whereas UNF stands for unified fine pitch threads. UNF threads are distinguished by having more threads per distance than UNC threads. While both UNC and UNF bolts are used for fastening, they are often applied in different fields due to their unique advantages.

For example, the coarse threads on UNC bolts are incredibly versatile and resistant to damage, making them the standard choice for most lower-tolerance, general purpose applications. On the other hand, the fine threads on UNF bolts give them higher tensile strength, making them useful for machine part assembly and other high precision applications.

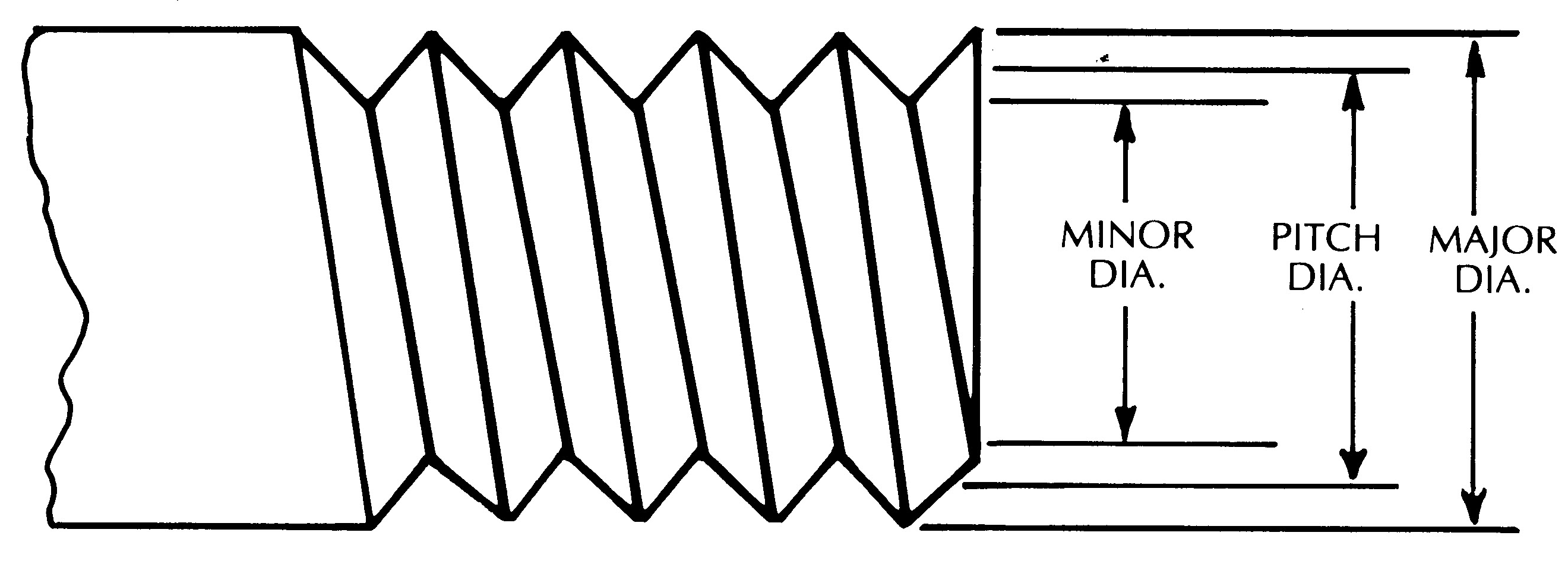

Measuring Bolt Dimensions & Diameters

The size of a bolt is determined by the diameter of the bolt’s shank (separate from the bolt head). Bolt diameter is typically separated into three categories:

- Major diameter: The largest and most outer diameter of a bolt’s shank.

- Pitch diameter: The diameter where the thread thickness = the space between threads.

- Minor diameter: The smallest and most inside diameter of a bolt’s shank.

Bolt Size Chart

Refer to the table for dimensions of commonly used bolt sizes. Measurements on top row represent UNC threads and measurements on bottom row represent UNF threads. Class 2A is acceptable for the majority of applications and Unified Thread Standard (UTS) bolt classes.

|

Size |

Threads Per Inch |

Class Thread |

Major Diameter Min Max |

Pitch Diameter Min Max |

Minor Diameter |

||

|

1/4 |

20 |

2A |

0.2489 |

0.2408 |

0.2164 |

0.2127 |

0.1876 |

|

28 |

2A |

0.2490 |

0.2425 |

0.2258 |

0.2225 |

0.2052 |

|

|

5/16 |

18 |

2A |

0.3113 |

0.3026 |

0.2752 |

0.2712 |

0.2431 |

|

24 |

2A |

0.3114 |

0.3042 |

0.2843 |

0.2806 |

0.2603 |

|

|

3/8 |

16 |

2A |

0.3737 |

0.3643 |

0.3331 |

0.3287 |

0.2970 |

|

24 |

2A |

0.3739 |

0.3667 |

0.3468 |

0.3430 |

0.3228 |

|

|

7/16 |

14 |

2A |

0.4361 |

0.4258 |

0.3897 |

0.3850 |

0.3485 |

|

20 |

2A |

0.4362 |

0.4281 |

0.4237 |

0.3995 |

0.3749 |

|

|

1/2 |

13 |

2A |

0.4985 |

0.4876 |

0.4485 |

0.4435 |

0.4041 |

|

20 |

2A |

0.4987 |

0.4906 |

0.4662 |

0.4619 |

0.4374 |

|

|

9/16 |

12 |

2A |

0.5609 |

0.5495 |

0.5068 |

0.5016 |

0.4587 |

|

18 |

2A |

0.5611 |

0.5524 |

0.5250 |

0.5205 |

0.4929 |

|

|

5/8 |

11 |

2A |

0.6234 |

0.6113 |

0.5644 |

0.5589 |

0.5119 |

|

18 |

2A |

0.6236 |

0.6149 |

0.5875 |

0.5828 |

0.5449 |

|

|

3/4 |

10 |

2A |

0.7482 |

0.7353 |

0.6832 |

0.6773 |

0.6255 |

|

16 |

2A |

0.7485 |

0.7391 |

0.7079 |

0.7029 |

0.6718 |

|

|

7/8 |

9 |

2A |

0.8731 |

0.8592 |

0.8009 |

0.7946 |

0.7368 |

|

14 |

2A |

0.8734 |

0.8631 |

0.8270 |

0.8216 |

0.7858 |

|

|

1 |

8 |

2A |

0.9980 |

0.9830 |

0.9168 |

0.9100 |

0.8446 |

|

12 |

2A |

0.9982 |

0.9868 |

0.9441 |

0.9382 |

0.8960 |

|

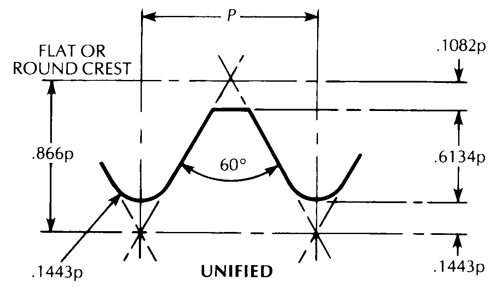

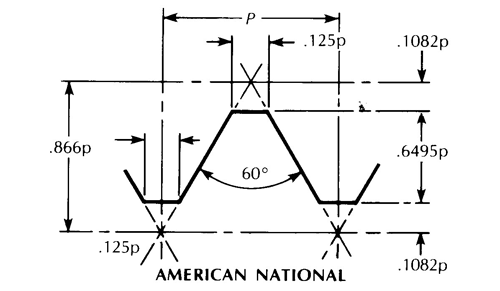

NC Thread Profiles

Unified

American National

Oster Bolt Threading Capabilities

No matter your bolt threading specifications, we have an extensive selection of industrial grade pipe and bolt threading machines to meet the requirements for any industry, including construction, military & defense, manufacturing, and fabrication. Our reliable 792ALX bolt threading machine can produce Class 2A threads ranging from ¼” to 2”—no skilled operator necessary.

We also manufacture high-performance dark thread cutting oil to ensure your threading machine works efficiently and effectively. Browse our selection of high quality, easy-to-use bolt threading machines and additional threading necessities. Read more about the applications and benefits of bolt threading.

Discuss Your Bolt Threading Needs with Us Today

As a customer-centric manufacturer, Oster is committed to providing you with exceptionally designed and durable pipe and bolt threading machines. Discuss your project with us or request a quote and order your threading machine today.